Impumelelo okanye ukusilela ukusetyenzwa kweplastiki ubukhulu becala kuxhomekeke kwisiphumo soyilo lokungunda kunye nomgangatho wokwenziwa ngundo, kunye noyilo lokungunda lweplastiki lusekelwe kuyilo oluchanekileyo lweemveliso zeplastiki.

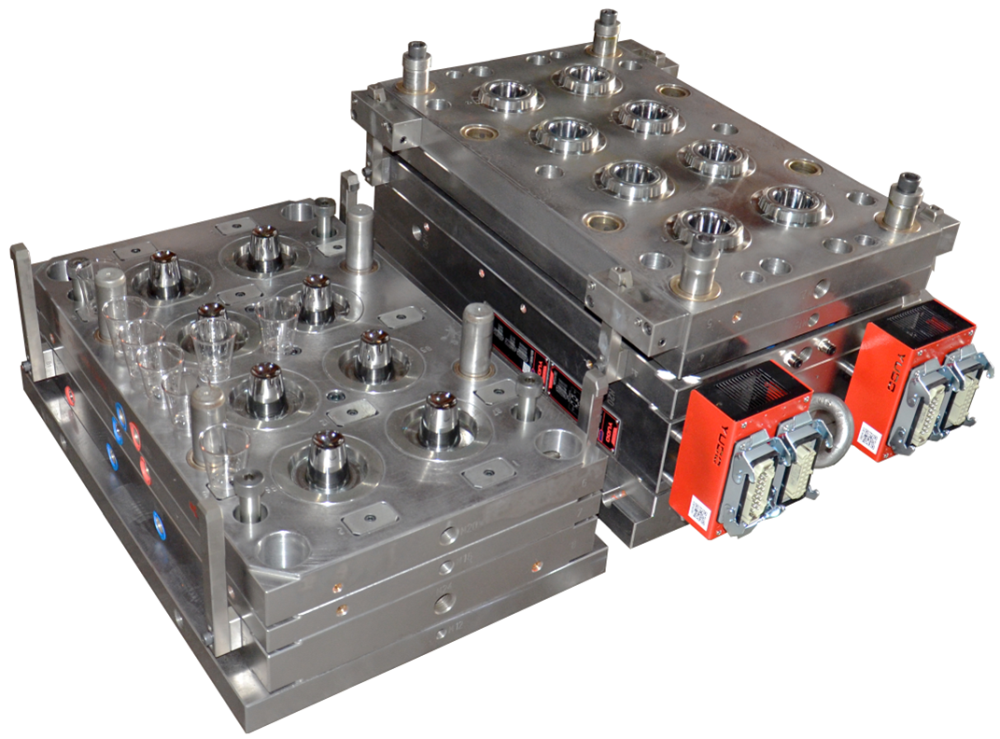

Izinto zolwakhiwo eziza kuqwalaselwa kuyilo lokubumba iplastiki ziquka:

① Umphezulu wokwahlulahlula, oko kukuthi, umphezulu wonxibelelwano phakathi kwemazi kunye nendoda iyafa xa kufa ivaliwe.Ukukhethwa kwesikhundla sayo kunye nefom ichaphazeleka yimiba efana nokuma kwemveliso kunye nokubonakala, ubukhulu bodonga, indlela yokwenza, iteknoloji ye-post-processing, uhlobo lokubumba kunye nesakhiwo, indlela yokudiliza kunye nesakhiwo somatshini wokubumba.

② Iindawo zesakhiwo, oko kukuthi ibhloko etyibilikayo, umphezulu othambekileyo, ibhloko ephezulu ethe ngqo, njl.Uyilo lwamalungu olwakhiwo lubaluleke kakhulu, olunxulumene nobomi benkonzo, umjikelo wokucubungula, iindleko kunye nomgangatho wemveliso yokufa.Ke ngoko, uyilo lolwakhiwo oluntsonkothileyo lwe-die core lufuna isakhono esiphezulu somyili, kwaye silandela isikimu esilula, esihlala ixesha elide kunye nesimo soqoqosho ngakumbi kangangoko kunokwenzeka.

③ Ukuchaneka kokufa, oko kukuthi, ukuphepha kwekhadi, ukubekwa kakuhle, indawo yesikhokelo, iphini yokubeka, njl.Iindlela ezahlukeneyo zokubeka zikhethwa ngokwezakhiwo ezahlukeneyo zokungunda.Ulawulo lokuchaneka kokumisa ubukhulu becala luxhomekeke ekuqhubeni, kwaye indawo yokubumba yangaphakathi iqwalaselwa ikakhulu ngumyili ukuyila indlela esengqiqweni nelula yokulungisa indlela yokubeka.

② Inkqubo yokungena, oko kukuthi, umjelo wokutya ovela kwi-nozzle yomshini wokubumba umjovo ukuya kwi-mold cavity, iquka i-channel ye-shunt, isango kunye ne-cold material cavity.Ngokukodwa, ukukhethwa kwendawo yesango kufuneka kube kulungele ukuzalisa umgodi wokubumba ngeplastiki etyhidiweyo phantsi kwemeko yokuhamba kakuhle, kwaye umgijimi oqinileyo kunye nezinto ezibandayo zesango eziqhotyoshelwe kwimveliso zilula ukukhutshwa kwi-mold kwaye zisuswe ngexesha lokuvula isikhunta. ngaphandle kokungunda kwembaleki eshushu).

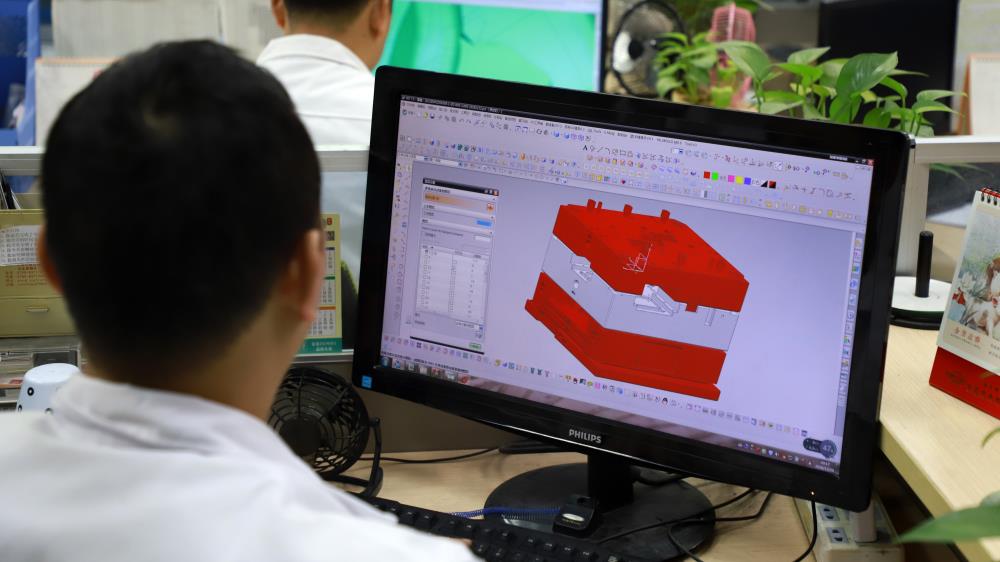

③ Ukuncipha kwePlastiki kunye nezinto ezahlukeneyo ezichaphazela ukuchaneka komgangatho weemveliso, ezinje ngokwenziwa kokungunda kunye neempazamo zokudityaniswa, ukunxiba kokungunda njalo njalo.Ukongeza, ukuhambelana kwenkqubo kunye neeparitha zesakhiwo somatshini wokubumba kufuneka kwakhona kuqwalaselwe xa kuyilwa i-mold compression kunye ne-injection mold.Itekhnoloji yoyilo encediswa yikhompyuter isetyenziswe ngokubanzi kuyilo lokubumba iplastiki.

Luluphi uyilo lwenkqubo yokukhupha umngundo weplastiki?

Isitofu sokungunda yinxalenye eyimfuneko yokubumba inaliti.Sazise imigaqo yoyilo lobungakanani bomgodi, indawo yesango, imbaleki eshushu, umzobo wendibano kunye nokukhethwa kwezinto zokubumba inaliti.Namhlanje siza kuqhubeka nokwazisa uyilo lwenkqubo yokukhupha isitofu seplastiki sokungunda.

Ukongeza kumoya wokuqala kwi-cavity, irhasi ekwi-cavity ikwaqulathe iirhasi ezisezantsi zemolekyuli eziguquguqukayo eziveliswe kukufudumeza okanye ukunyangwa kwezixhobo zokubumba inaliti.Kuyimfuneko ukuqwalasela ukukhutshwa okulandelelanayo kwezi gesi.Ngokuqhelekileyo, kwi-mold enesakhiwo esiyinkimbinkimbi, kunzima ukuqikelela indawo echanekileyo yokutshixa umoya kwangaphambili.Ngoko ke, ngokuqhelekileyo kuyimfuneko ukumisela indawo yayo ngovavanyo lokufa, kwaye emva koko uvule i-slot yokukhupha.I-exhaust slot idla ngokuvulwa apho u-Z ugcwele khona.

Imowudi yokukhupha kukuvula i-slot yokukhupha i-exhaust ngokusebenzisa i-clean ehambelanayo yeendawo zokufa.

Ukubunjwa kweendawo ezibunjiweyo zenaliti zifuna ukukhupha, kwaye ukuchithwa kweendawo ezibunjiweyo zenaliti kufuna ukukhupha.Kwindawo yokubumba iqokobhe elinzulu, emva kokubunjwa kwenaliti, irhasi emngxunyeni iyavuthelwa.Kwinkqubo ye-demoulding, i-vacuum yenziwa phakathi kokubonakala kweengxenye zeplastiki kunye nokubonakala kwengundoqo, okunzima ukuyidiliza.Ukuba ukuchithwa ngenkani, iindawo ezibunjiweyo zenaliti zilula ukukhubaza okanye ukonakala.Ngoko ke, kuyimfuneko ukwazisa umoya, oko kukuthi, phakathi kwesitofu esibunjiweyo inxalenye kunye nengundoqo, ukwenzela ukuba i-plastic naliti ebunjiweyo inxalenye inokuchithwa kakuhle.Kwangaxeshanye, iigrooves ezininzi ezingenzulwanga ziyacutshungulwa kumphezulu wokwahlula ukuze kube lula ukukhupha.

1. Ithempleyithi yomgodi kunye nondoqo kufuneka kusetyenziswe ibhloko yokubeka i-conical okanye ibhloko yokubeka echanekileyo.Isikhokelo sifakwe kumacala amane okanye ngeenxa zonke kwi-mold.

2. Umphezulu wokudibanisa phakathi kweplate yesiseko sokubumba kunye nentonga yokusetha kwakhona kufuneka isebenzise i-flat pad okanye i-pad ejikelezayo ukuphepha ukulimaza ipleyiti.

3. Inxalenye ye-perforated ye-rail yesikhokelo iya kuthambekela ngaphezu kwe-2 degrees ukuphepha i-burrs kunye ne-burrs.Inxalenye enemingxuma ayiyi kuba yesakhiwo se-blade encinci.

4. Ukuze kuthintelwe i-dents kwiimveliso ezibunjiweyo zenaliti, ububanzi be-stiffener buya kuba ngaphantsi kwe-50% yobunzima bodonga lwembonakalo yomphezulu (ixabiso elifanelekileyo <40%).

5. Ubunzima bodonga lwemveliso buya kuba lixabiso eliphakathi, kwaye ubuncinane utshintsho olukhawulezayo luya kuqwalaselwa ukuphepha ukubola.

6. Ukuba icandelo elibunjiweyo lenaliti lifakwe kwi-electroplated, ukungunda okushukumayo nako kufuna ukupolishwa.Iimfuno zokuhombisa zesibini kuphela kwiimfuno zokugulisa isibuko ukunciphisa ukuveliswa kwezinto ezibandayo kwinkqubo yokwenza.

7. Iimbambo kunye neegrooves kwimingxuma engena moya kunye neecores kufuneka zifakwe ngaphakathi ukuthintela ukunganeliseki kunye namanqaku okutshisa.

8. Ukufakwa, ukufakwa, njl. kuya kubekwa kwaye kulungiswe ngokuqinileyo, kwaye idiski iya kunikwa amanyathelo okuchasana nokujikeleza.Akuvumelekanga ukupakisha ubhedu kunye nentsimbi phantsi kokufaka.Ukuba i-welding pad iphezulu, inxalenye edibeneyo iya kwenza uqhagamshelwano olukhulu kunye nomgangatho ophantsi.

Ixesha lokuposa: Mar-10-2022